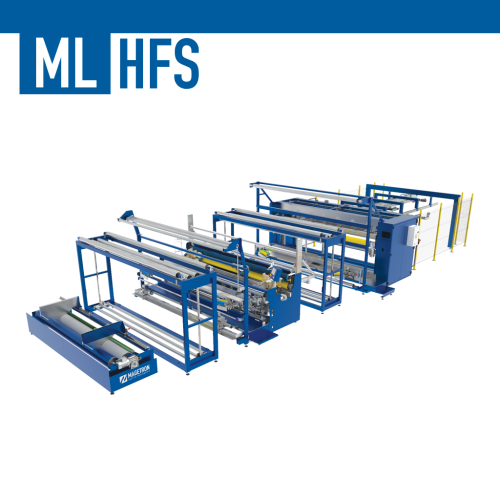

THREE SOLUTIONS, ONE TECHNOLOGY

U-shaped (WxL): both sides length hemming & sewing, doubling (folding), cross cutting, label dispensing, sides closing (overlocking), stacking

U-shaped (LxL): cross cutting, label dispensing, cross hemming & sewing, doubling (folding), side overlocking, stacking.

L-shaped: right side length hemming & sewing, doubling (folding), cross cutting, label dispensing, cross and bottom overlocking, stacking.

Automatic turning group can be connected with each machine.

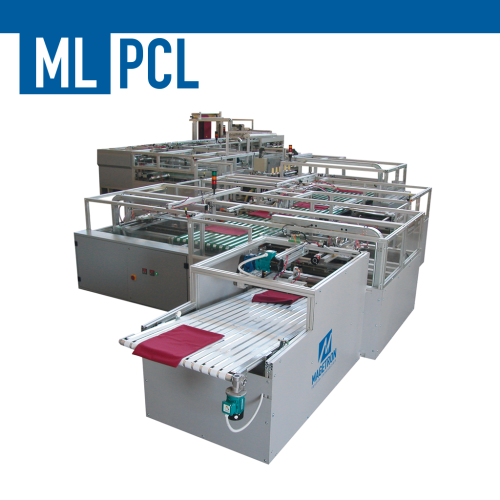

The Magetron ML-PCL takes over the complete processing procedure with extraordinary performance, uncompromising quality and flexibility.

PRODUCTIVITY AND OUTSTANDING QUALITY

Three complete lines for the making up of pillow cases grant the most complete choice in the production process. Each line is realized in order to maximize and optimize productivity and efficiency.

REAL AUTOMATION

From the roll to a perfect quality of the final product. Thanks to technological development, to engineering and to innovative solutions, it is possible to produce pillow cases with an extraordinary level of quality.

MULTIPURPOSE SOLUTION

Depending on the configuration this machine can be used for producing even cushion and pillow ticks providing an high level of versatility and flexibility.

For further information download brochure or contact us!.

Reviews

There are no reviews yet.